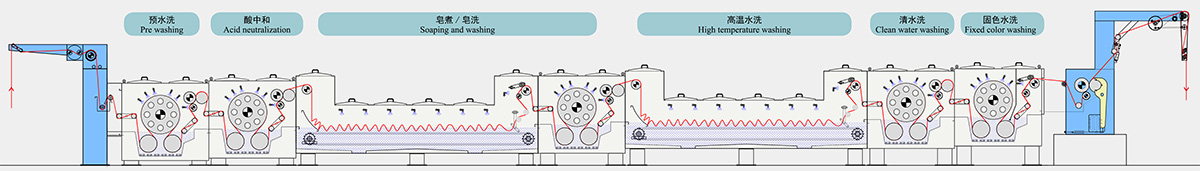

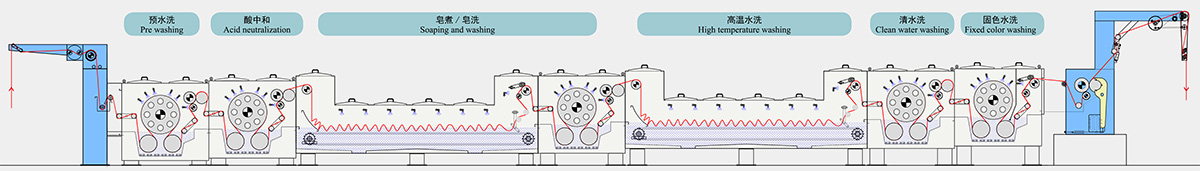

Open Width Washing Machine After Dyeing For Knitted Fabric

Machine speed:60m/min

Working width:1800-3600mm

Heating method:Steam

Steam and compressed air pressure:0.4MPa

Total power:55KW

Overall dimension(Type220):(L×W×H)24400×4100×2900mm

Description

';

';

※Machine Use

Open width washing process after dyeing of cotton, T / C, CVC and other knitted fabrics.

※Energy Consumption

Production capacity: 0.8 tons of cloth per hour

Water consumption: 4-8 tons of water is consumed to produce 1 ton of cloth

Steam consumption: 0.4-0.8 tons of steam is consumed to produce 1 ton of cloth

※Machine Features

Machine speed:60m/min

Working width:1800-3600mm

Heating method:Steam

Steam and compressed air pressure:0.4MPa

Total power:55KW

Overall dimension(Type220):(L×W×H)24400×4100×2900mm

※Machine Advantage

·German imported tension control system to ensure low tension operation

·High speed response of Schneider high end communication inverter in France

·Electric control response time 0.4ns, Constant tension 0.6kg

·Conical high-pressure spray, no dead angle for water washing

·Automatic feeding and liquid level detection system

·Horizontal rolling mill to ensure no curling before rolling point

·Automatic filtration system for both the water wash tank and the soap cooking tank

※Energy Consumption Comparison

| Compared items | Open width washing | Dyeind vessel washing | Save |

| Water consumption | 8.5L/kg(cloth) | 86L/kg(cloth) | 86% |

| Electricity consumption | 0.034kwh/kg(cloth) | 0.124kwh/kg(cloth) | 72% |

| Steam consumption | 0.58kg/kg(cloth) | 2.68kg/kg(cloth) | 78% |

| Production capacity:800kg cloth/h,with an average energy saving of 79.2% | |||