Open Width Cold Pad Dyeing Line For Knitted Fabri

Machine speed:60m/min

Working width:1800-3600mm

Compressed air pressure:0.4MPa Total power: 17KW

Rolling mill type:Horizontal uniform rolling mill

Feeding system:Automatic feeding of mixing proportion pump produced in Germany

Overall dimension(Type220):(L×W×H)5000×3630×2600mm

Description

※Machine Use

Open width cold pad dyeing process of cotton, T/C, CVC and other knitted fabrics.

※Energy Consumption

Production capacity: 0.8 tons of cloth per hour

Water consumption: 1 tons of water is consumed to produce 1 ton of cloth

Steam consumption: No steam required

※Machine Features

Machine speed:60m/min

Working width:1800-3600mm

Compressed air pressure:0.4MPa Total power: 17KW

Rolling mill type:Horizontal uniform rolling mill

Feeding system:Automatic feeding of mixing proportion pump produced in Germany

Overall dimension(Type220):(L×W×H)5000×3630×2600mm

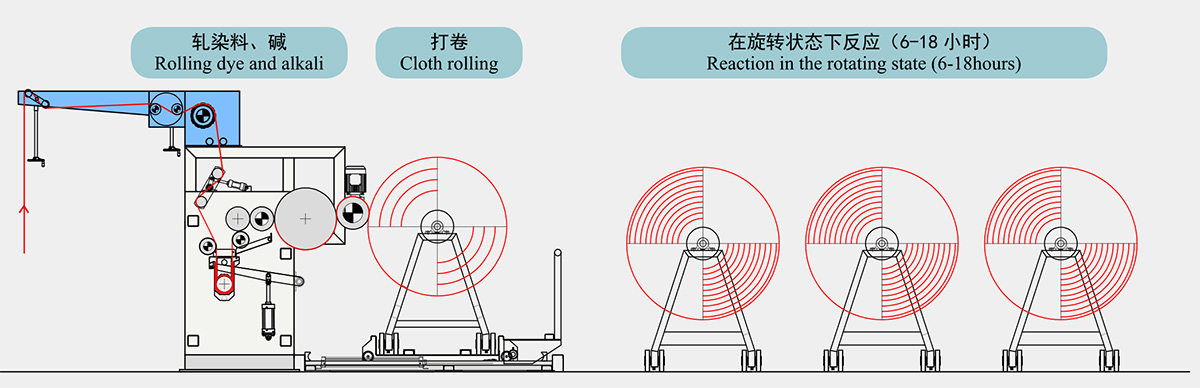

※Process Introduction

Cold stack dyeing process is a kind of new dyeing process which is adapted to the size of the knitted fabric. The process of dyeing the knitted fabric through the mixture of dyestuff and alkali is carried out at natural temperature. At natural temperature, the dyestuff is rotated slowly to make the dye diffusion and fixation reaction, thus a new dyeing process is completed, which is adapted to the batch processing of the size of the knitted fabric. It belongs to the salt free dyeing, and the sewage is easy to handle.

※The Effect of Cloth

The fabric is flat, No creases, No feather, Clear lines and soft hand feel, Especially suitable for improving the dimensional stability of elastic knitted fabric.

※Conclusion of Cold Pad Dyeing

(1)Reactive dyes are used for cold pad batch dyeing of cotton, polyester cotton and cotton spandex fabrics, with high fixation rate and less dye waste. Under the condition of supporting equipment, the process is stable and reliable.

(2)After cold pad batch dyeing and finishing, the cotton knitted fabric has flat surface, no crease, no hairiness, clear lines and soft hand feel. Production practice shows that cold pad batch dyeing process can not only improve the quality of products, but also be especially suitable for improving the dimensional stability of elastic knitted fabrics.

(3)Cold pad batch dyeing equipment has the advantages of small floor area, short preparation period, flexible production and wide applicability.

(4)Cold pad batch dyeing process, with low energy consumption, water consumption and sewage discharge, reduces production cost and meets the requirements of sustainable development, is a recommended green environmental protection dyeing process in the printing and dyeing industry.

※Treatment effect

·No wrinkles, No curls, No pilling

·No hairiness, No scratch,Even cloth surface

·Stable weight and uniform color