Open Width Cold Pad Bleaching Line For Knitted Fabric

Machine speed: 60m/min

Working width:1800-3600mm Heating method: Steam

Steam and compressed air pressure: 0.4MPa

Total power: Cold stack unit: 15KW Steam washing unit: 60KW

Overall dimension(Type220):

Cold stack unit: (L×W×H) 6330×3220×2700mm

Steam washing unit: (L×W×H)22500×4100×2900mm

Description

※Machine Use

Open width widfh cold pad bleaching and washing process of cotton, T/C, CVC and other knitted fabrics.

※Energy Consumption

Production capacity: 0.75 tons of cloth per hour

Water consumption: 6.28 tons of water is consumed to produce 1 ton of cloth

Steam consumption: 0.45 tons of steam is consumed to produce 1 ton of cloth

※Machine Features

Machine speed: 60m/min

Working width:1800-3600mm Heating method: Steam

Steam and compressed air pressure: 0.4MPa

Total power: Cold stack unit: 15KW Steam washing unit: 60KW

Overall dimension(Type220):

Cold stack unit: (L×W×H) 6330×3220×2700mm

Steam washing unit: (L×W×H)22500×4100×2900mm

※Machine Introduction

cold stack bleaching washing machine for open width knitted fabric is pre-treatment, bleaching and washing by cold padder and stack technology. Advanced production technology combined with mechanical equipment, the quality and stability of products have been greatly improved. The machine is made up of dipping and steaming parts. Firstly, chemical additives and treatment liquid are applied through the dipping and rolling part, then the treated fabric is foiled or stacked for 4-6 hours, and then steaming, washing and neutralizing through the steam washing part.

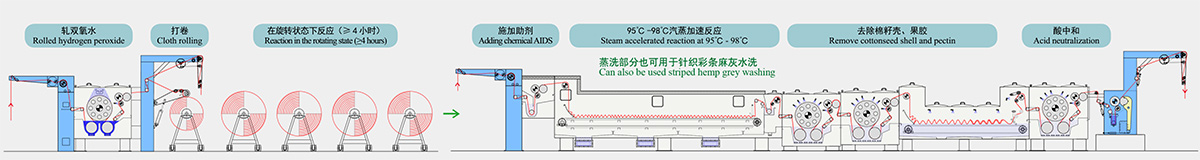

※Technological Steps

Normal temperature dip rolling working solution → Sealed stacking at 25-30℃ for 4 hours → Steaming, washing,neutralization → Direct dyeing

※Machine Advantage

The conventional treatment is intense, the friction is larger, the hairiness is more, and easily to cause folds, while the cold stack process is mild and the whiteness is uniform, and the cloth face is bright, smooth and soft.

※Energy Consumption Comparison

| Compared items | Cold Pad Bleaching | Dyeing vessel Bleaching | Save |

| Water consumption |

6.28L/kg (Cloth) |

22.28L/kg (Cloth) | 71.65% |

| Electricity cinsumption |

0.023kwh/kg (Cloth) |

0.048kwh/kg (Cloth) | 52.27% |

| Steam cinsumption |

0.45kg/kg (Cloth) |

1.41kg/kg (Cloth) | 68.05% |