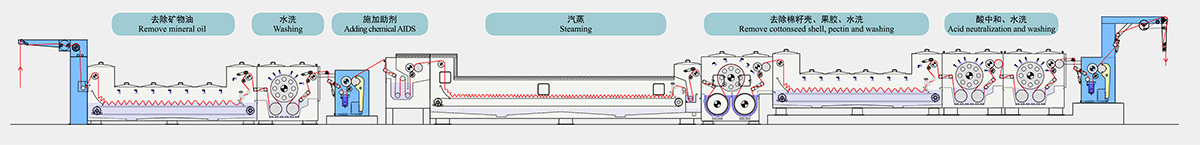

Open Width Continuous Bleaching Line For Knitted Fabric

Machine speed:60m/min

Working width:1800-3600mm

Heating method;Steam

Steam and compressed air pressure:0.4MPa

Total power:88KW

Overall dimension(Type220):(L×W×H)36000×4100×2900mm

Description

※Machine Use

Open width continuous bleaching and washing process of cotton, T/C, CVC and other knitted fabrics.

※Energy Consumption

Production capacity:0.85 tons of cloth per hour

Water consumption:8-12 tons of water is consumed to produce 1 ton of cloth

Steam consumption:0.7-1.2 tons of steam is consumed to produce 1 ton of cloth

※Machine Features

Machine speed:60m/min

Working width:1800-3600mm

Heating method:Steam

Steam and compressed air pressure:0.4MPa

Total power:88KW

Overall dimension(Type220):(L×W×H)36000×4100×2900mm

※Machine Advantage

Automatic Control System

·Imported electrical control system

·Tension real-time monitoring, constant tension operation

·One key start and buffer pressurization of rolling mill

·Automatic feeding and liquid level detection system

Running low tension no curling

·Tension sensor imported from Germany

·Schneider high end electrical control system

·Communication line transmission signal

·Response time: 4ns, Constant tension: 0.6kg

Better treatment effect than conventional process

·No hairiness, No scratch, Smooth and bright cloth surface

·No fold, No curl ,No pilling

·Conical spray, full coverage water washing, strong washing power

·Fabric weight stability, Whiteness, Color left center right uniform

Low energy consumption than dyeing vessel

·Chemical consumption can be saved by 25%

·Water consumption can be saved by 60%

·Steam consumption can be reduced by 65%

·Electricity consumption can be reduced by 45%

Pre:没有了!