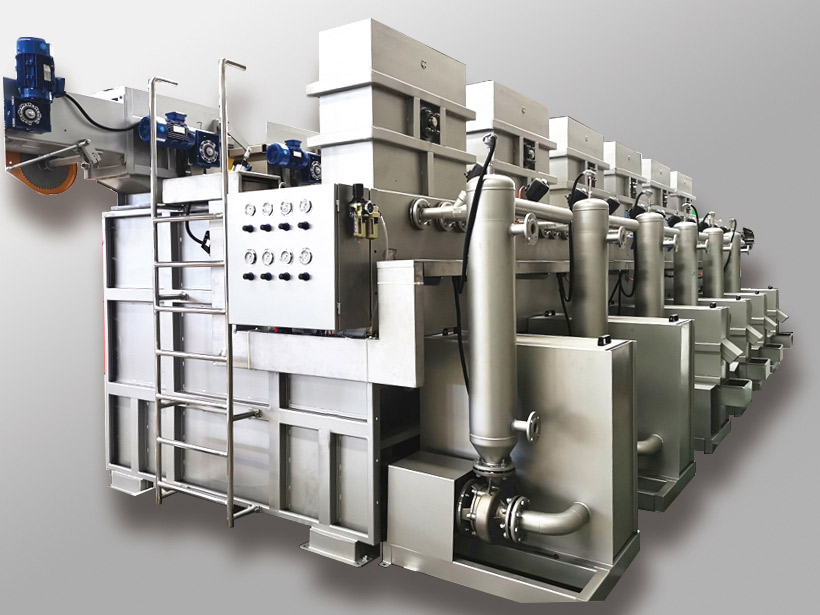

Rope type continuous wash

Introduction

This machine is a rope continuous washing machine:

1. Reasonable structure design high degree of automation simple operation and less labor;

2. The cabinets are arranged compactly and occupy a small area;

3. The maximum cloth capacity of each tank is 100 meters and the soaping time is sufficient;

4. The cloth of two adjacent grooves of each unit is flushed back and forth through the cloth lifting wheel and nozzle with strong washing power;

5. The overall water flow is grid by grid with high water utilization rate and low water consumption. Wide range of technology high production speed strong applicability and other characteristics.

Description

';

';

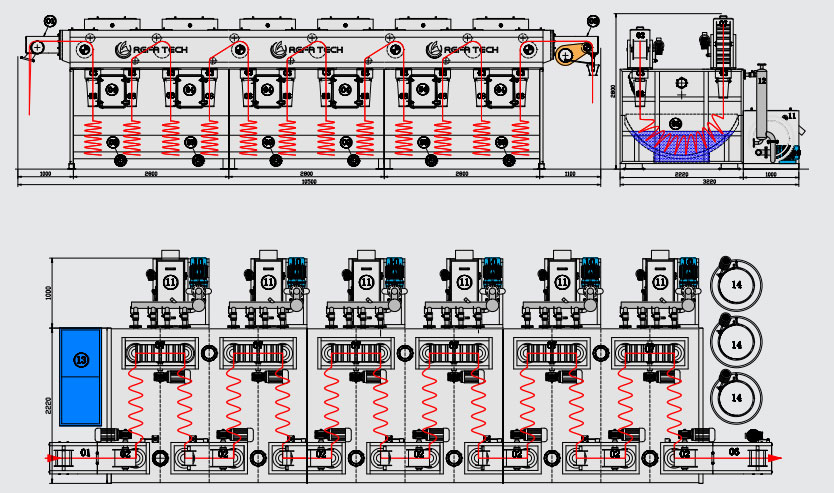

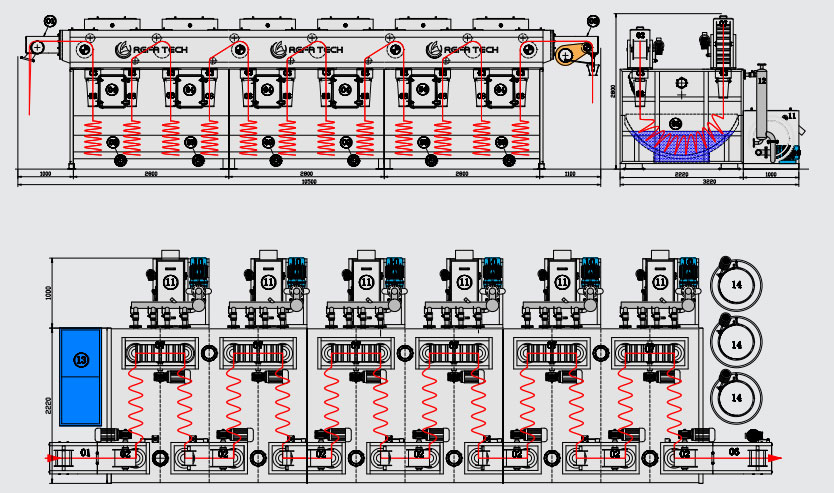

※working principle

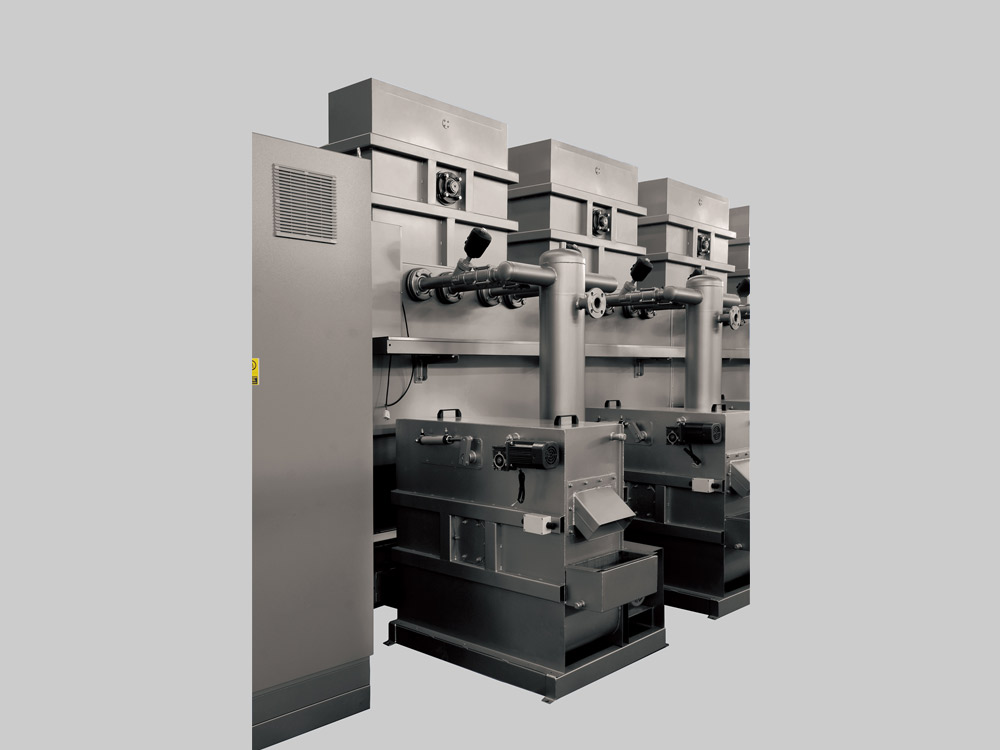

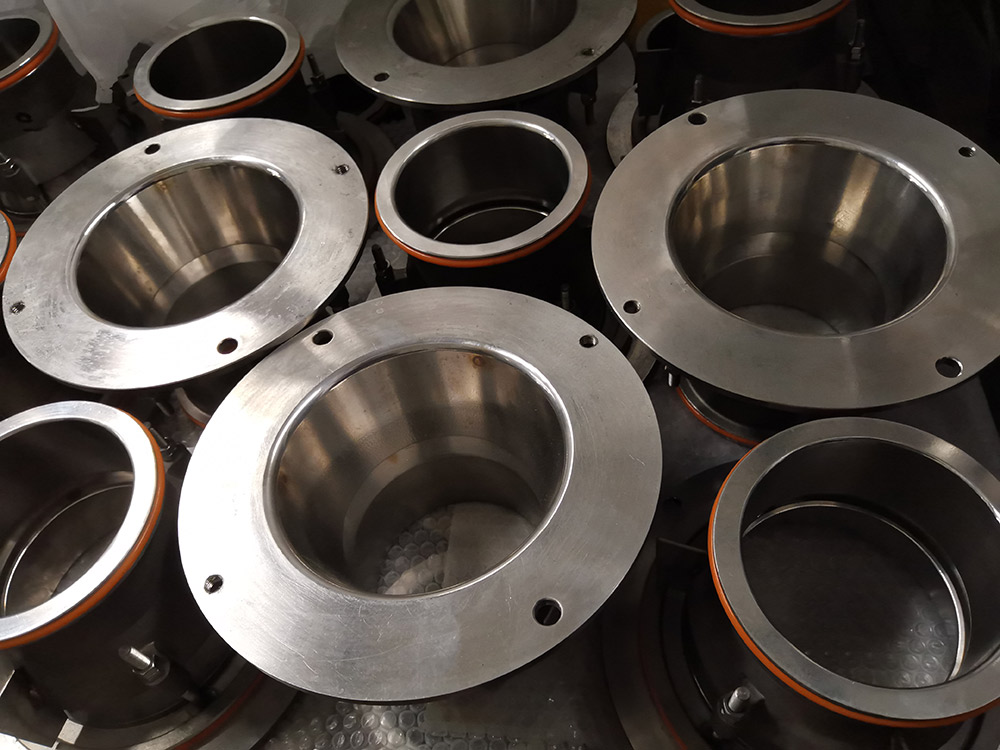

The machine adopts the modular combination method, each group of modules is composed of 4 cylinders and 8 nozzles. Fully enclosed design, greatly saving steam, small footprint and high washing efficiency.

The fabric reciprocates through 4 nozzles every minute, and the fabric is continuously washed in retrograde and antegrade. The cloth surface is continuously switched with water to achieve efficient, strong and sufficient washing effect.

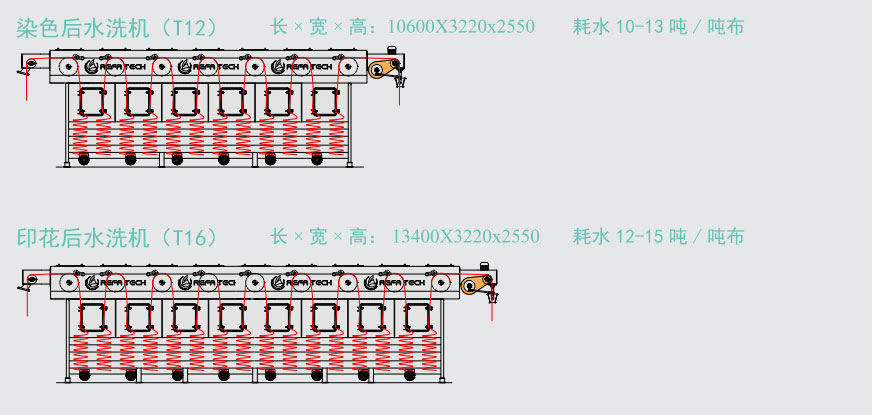

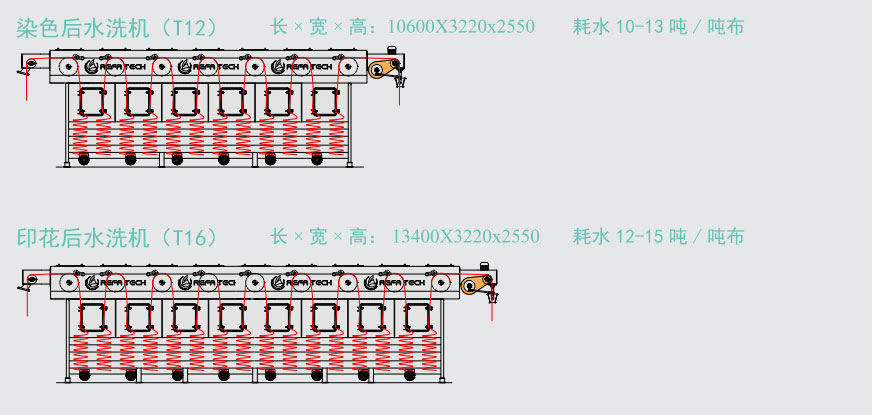

※Equipment introduction

※technical parameter

Power supply: 3Φ.380VAC.50Hz

Installed capacity: 28KW; 56A

Mechanical speed: 50m/min

Steam pressure: 6~7kgf/cm3 (pipe diameter DN50)

Clean water pressure: 3~4kgf/cm3 (pipe diameter DN65)

Compressed air pressure: 5~64kgPcm3 (pipe diameter DN20)

※Applicable process

Pre-bleaching, all white, fluorescent whitening, enzyme washing, anti-pilling

Rope continuous dyeing

Wash after dyeing

Yeast washing, hair erosion

Loose Desizing of Denim Yarn-dyed Fabric

The cylindrical fabric is mercerized and then neutralized and washed

Wash after traditional, digital printing

※Equipment advantages

Small footprint

Low energy consumption of hydropower

Multifunction

Easy operation

※Device parameters

Machine speed: 60m/min

Working width: 1800-3600mm

Heating method: steam 0.6~0.7MPa

Fabric storage capacity per cylinder: about 100 meters

Electric drive: AC frequency conversion, PLC, man-machine interface

※Equipment use

·Pre-bleaching

·All white, fluorescent whitening

·Anti-pilling, yeast washing, hair erosion

·Relaxed desizing of denim yarn-dyed fabric

·The cylindrical fabric is mercerized and then neutralized and washed

·Wash after traditional and digital printing

·Wash after dyeing

※Applicable fabric

Knitted fabric (cylinder, open width), woven fabric

※Process flow

Pre:没有了!

Next:没有了!