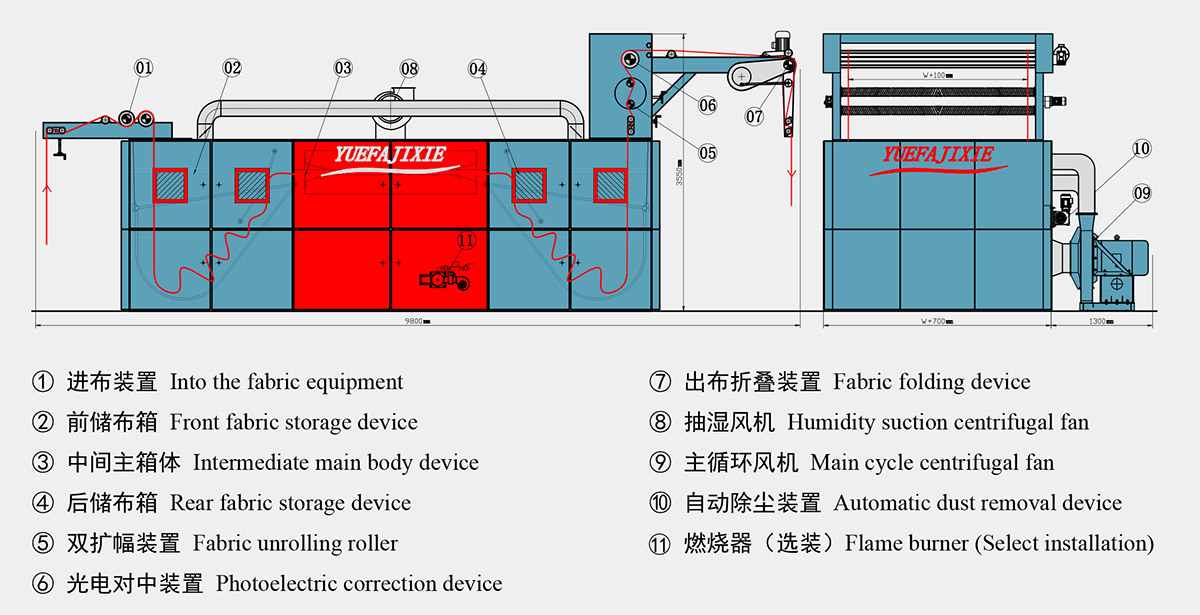

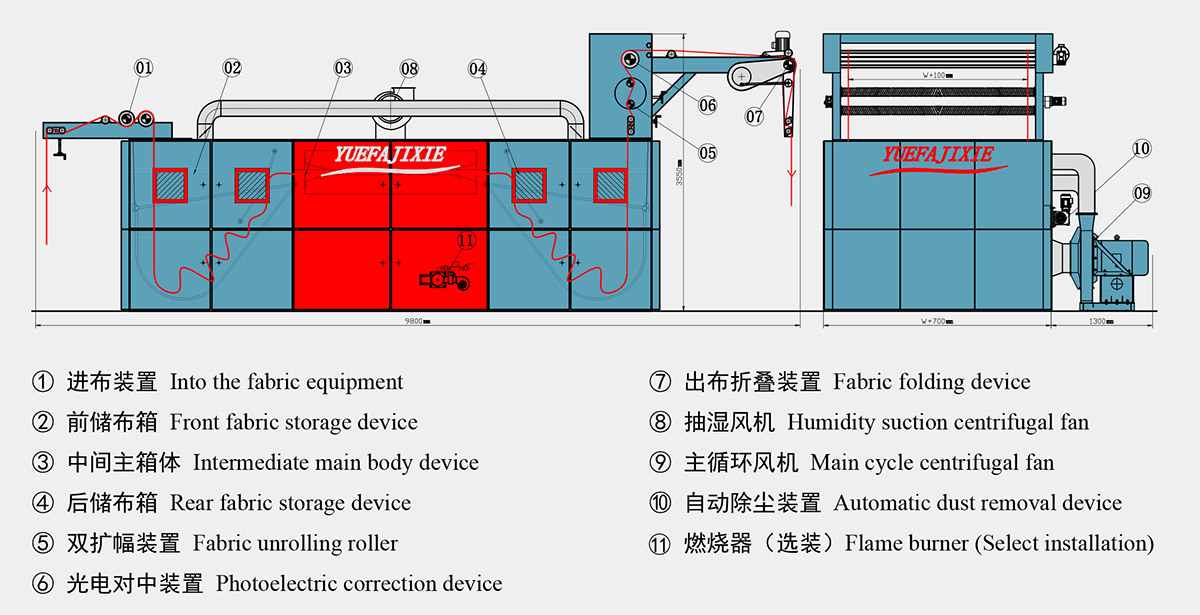

Open Width Airflow Softening Drying Machine

Machine speed:60m/min

Working width:1800~3600mm

Heating method:Steam、Natural gas、Heat transfer oil

Heating temperature:130℃ Steam、170℃ Natural gas or Heat transfer oil

Power consumption:65kw/h

Steam consumption:100-120kg/h

Nature gas consumption:8-10nm³/h

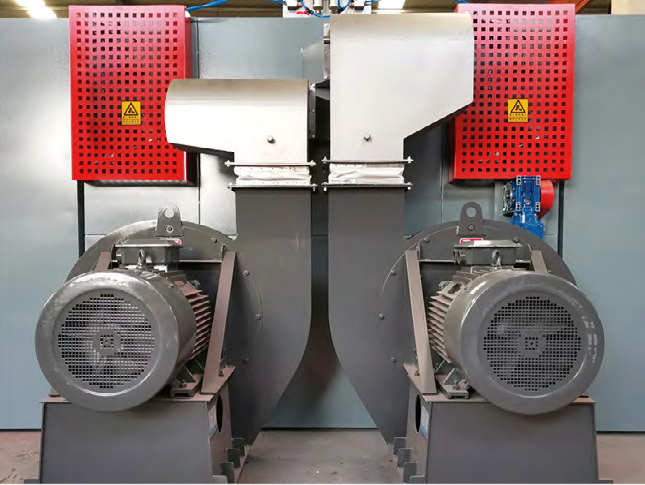

Description

';

※Suitable Fabric

●Natural fiber (Cotton, Linen, Ramie, Jute, Silk, Wool, Mixed fiber, etc.)

●Man-made fibers (Viscose, Copper ammonia fiber, Lisai fiber, Chinlon, Tencel, Lyocell, Modal, etc.)

●Synthetic fiber (Polyester, Nylon, Acrylic, PP, PU, PVC, etc.)

●All kinds of knitting, Weaving, Flocking and Non-woven fabrics

※Process Effect

●Soft, fluffy, drape, dimensional stability;

●Increase fabric elasticity and wrinkle resistance;

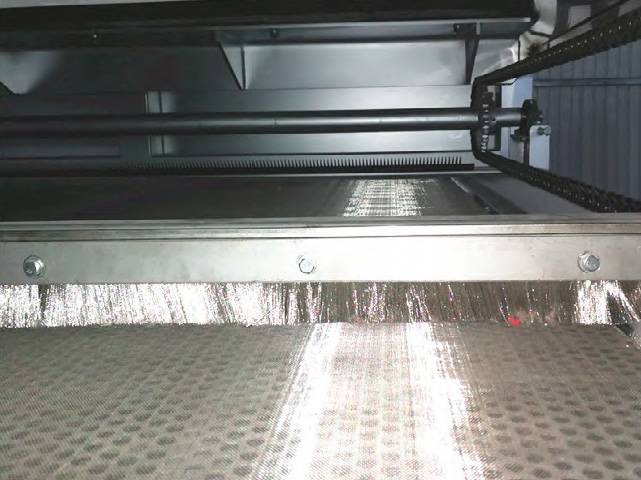

●It can remove the hairiness and dust of the cloth surface;

●For spandex fabric, it can play the role of pre-shrinking and drying;

It can be used as a knitted fabric to replace the washing machine and dryer, and it can play a pre-shrinking effect

※Energy Consumption Advantage

| YUEFA company | Other company | |

| Steam consumption | 100-120Kg/h | 700-800Kg/h |

| Natural gas consumption | 8-10nm³/h | 60-70nm³/h |

| Heat transfer oil consumption | 6-8m³/h | 30-40m³/h |

| Installed capacity | 96KW | 126KW |

| Dust removal device | Built-in type, no heat loss (hot air internal circulation, filter filter dust removal, brush automatic cleaning) | External type, the heat energy loss is huge (the hot air is filtered out and dusted out of the box after being used once) |

To sum up:

① YUEFA company's equipment saves 30 kWh per hour compared to other similar equipment, and saves 600 kWh per day by 20 hours per day.

② If the steam is heated, the YUEFA company's equipment saves 700kg per hour compared to other similar equipment. By 20 hours per day, it can save 14 tons of steam per day.

③ If the natural gas is heated, the YUEFA company's equipment saves 50 nm3per hour compared to other similar equipment. By 20 hours per day, it can save 1000 nm3 of natural gas per day. | ||

Pre:没有了!

Next:没有了!